Our Blog

Our Blog

Our Blog

¿Qué hay de nuevo en diciembre de 2025?

Dec 12, 2025

| Five well-spent minutes

What´s new on December 2025?

Highlights, insights, and interesting opportunities — let’s dive in!

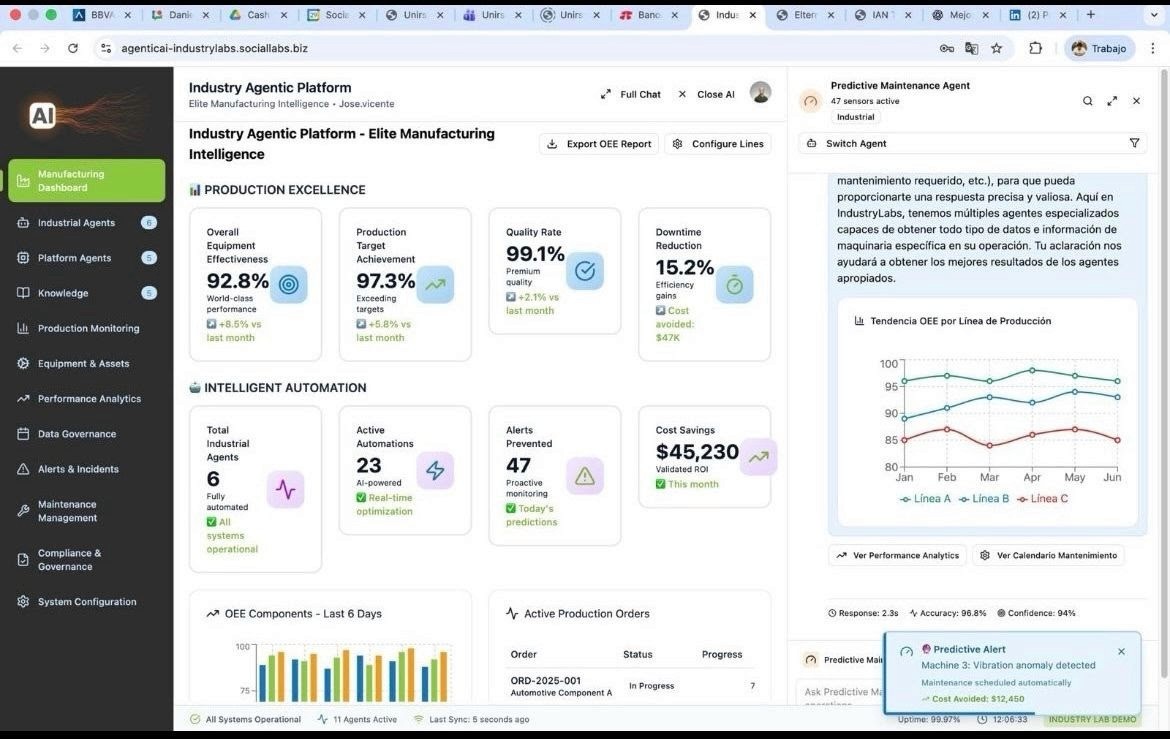

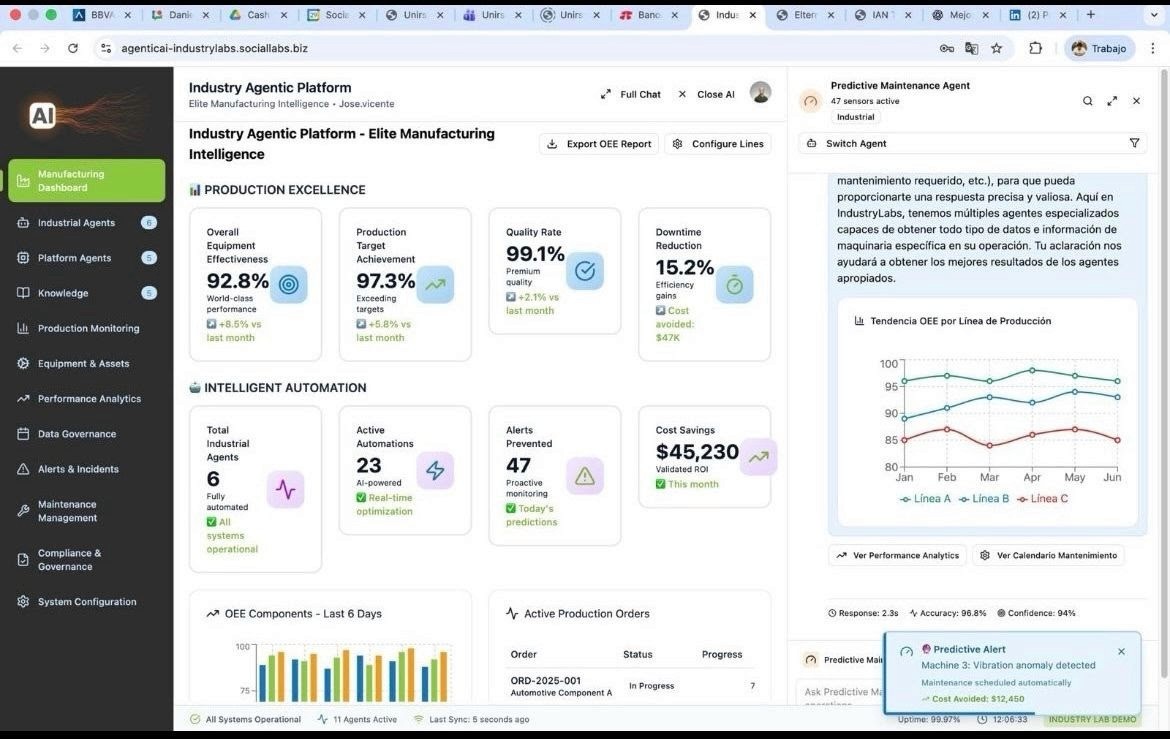

Agentic AI Orchestration and Governance by Industry Labs

Agentic AI only creates value in industry when it is built on a solid foundation of digitized core processes. The first step is to digitalize transactional processes with Industry MES, Industry APS, Industry SGA, which digitize and optimize operations and generate reliable data. Without this foundation, any attempt at AI becomes fragile and difficult to govern.

Once operational processes are digitized, the next level is to incorporate plant digitalization, in order to analyze OEE, explain downtime, and truly understand what is happening in the operation.

Only then does it make sense to advance toward the cognitive digitalization of critical business processes through Agentic AI Orchestration & Governance by Industry Labs, ensuring security, determinism, and a clear human-in-the-loop strategy, where AI assists and proposes, but human control remains.

The message is clear: the cognitive industry does not start with Agentic AI, it starts with well-digitized transactional processes. Those who follow this path will be able to scale intelligence in a safe and controlled way, with real impact on decision-making and a clear ROI.

Discover more at www.industrylabs.biz

Ready to get started? Write to us and let’s build together the next generation of intelligent industry.

Glossary (summary):

Agentic AI: AI based on specialized agents that reason and act under control rules.

MES: Manufacturing Execution System for real-time production execution.

APS: Advanced Planning and Scheduling of production.

SGA: Warehouse Management System for internal logistics and optimization.

OEE: Overall Equipment Effectiveness, a metric for the overall efficiency of production equipment.

Orchestration & Governance: the layer that governs and controls how AI agents act.

Human-in-the-loop: human supervision and decision-making over AI.

ROI: return on investment.

Industry Labs

Industry Labs Accelerates Its Growth in 2025 Through Alliances with SAP Gold Partners

In 2025, Industry Labs is accelerating its growth thanks to a clear and effective strategy based on alliances with SAP Gold Partners. Through these collaborations, Industry MES and Industry APS are natively integrated with SAP Business One and SAP ByDesign, transforming them into true industrial ERPs, capable of governing not only administrative management, but also production planning and execution.

This combination allows companies to keep SAP ERP as their corporate core while incorporating shop floor control, traceability, advanced planning, and operational optimization. The model is generating real and sustained business for Industry Labs , especially among industrial companies seeking efficiency and control without replacing their ERP. The outlook for these alliances is particularly strong in Central America, Mexico, South America, and Spain, where Industry Labs , together with SAP Gold Partners, is consolidating itself as a key player in industrial modernization and as the foundation for future cognitive digitalization.

Industry Labs

Industry Labs 2026: 360° Industrial Enablement, from Transactional Digitalization to Cognitive Intelligence

Looking ahead to 2026, Industry Labs is strengthening a very clear market positioning: we support our clients in a 360-degree journey, from the operational foundation to the cognitive layer of the business. Our culture is industrial—just like our clients’—and we have spent more than two decades building Advanced Manufacturing 4.0 solutions and platforms grounded in the reality of the shop floor.

That journey begins with the digitization and optimization of critical transactional operational processes, through the implementation of Industry MES, Industry APS, and Industry SGA, which structure and optimize execution, planning, and logistics, generating reliable data. On top of that foundation, we integrate plant intelligence through IIoT, to understand OEE, explain downtime, correlate performance, and anticipate deviations.

And only when processes and data are mature, we complete the journey with the cognitive digitalization of critical business processes through Industry Agentic AI Orchestration & Governance, always ensuring security, determinism, and a clear human-in-the-loop strategy.

The result is a more efficient, resilient, and aware industry, where technology does not just automate, but truly helps companies operate and decide better.

News of Interest for Our Clients

News of Interest for Industry Labs Clients in Spain

Spain postpones the entry into force of Verifactu, the electronic invoicing system promoted by the Tax Authority, until 2027

Spain has postponed the mandatory adoption of Verifactu until 2027 to facilitate the adaptation of companies and self-employed professionals, but the change is already underway. Verifactu introduces verifiable invoicing through certified software, with complete, traceable, and unalterable invoices, QR codes, and the possibility of automatic submission to the Tax Authority.

The new dates are: January 1, 2027 for Corporate Income Tax companies and July 1, 2027 for self-employed professionals. Even so, starting in 2025, invoicing software must comply with the technical requirements, so adaptation must begin in advance.

In this context, as of October 2025, the Industry ERP is already prepared to comply with Verifactu, allowing companies to get ahead, ensure traceability, and avoid last-minute rushes. Verifactu is not just about tax compliance: it requires reviewing ERPs, accounting processes, and compliance models. Those who prepare now will reduce risks and costs and will reach 2027 with a competitive advantage.

Do you have questions or need assistance? Write to us and we will be happy to help.

Manufacturing News Octubre - Diciembre 2025 by Industry Labs

During the last quarter of 2025, the global manufacturing industry has entered a phase of strategic adjustment and positioning for 2026. In addition to geopolitical volatility, there are clear signs of selective slowdown, more targeted investments, and a tangible acceleration in advanced digitalization, automation, and industrial intelligence.

Below is the country-by-country summary:

United States

Focus on Selective Reindustrialization and Operational Efficiency

PMI stabilized, without strong growth: The manufacturing index remained around 49–50during the quarter, reflecting stability without a clear recovery.

More pragmatic reindustrialization: Federal incentives continue, but with greater demands for returns and productivity. Modernization projects of existing plants are growing compared to new construction.

Automation as a priority: Increased investment in MES software, advanced planning, and industrial analytics to offset labor costs and inflationary pressure.

Source: Bloomberg, Wall Street Journal

México

More mature and demanding nearshoring

Nearshoring is consolidating: The pace of new investments remains steady, especially in automotive, food, and consumer goods, with strong demand for industrial digitalization.

Structural bottlenecks: Energy, water, and logistics remain critical factors that constrain the pace of expansion.

Shift in focus: Established companies are prioritizing operational efficiency, traceability, and shop floor control over purely volumetric growth.

Source: El Financiero, El Economista

Spain

Year-end marked by industrial digitalization

Industry and European funds: In the last quarter, projects financed by PERTEs and Next Generation fundsaccelerated, with a focus on digitalization and sustainability.

Strong interest in MES, APS, and IIoT: industrial SMEs are intensifying investments in Advanced Manufacturing platforms to improve productivity and resilience.

Preparing for 2026: the industrial agendaincreasingly incorporates operational intelligence concepts and early pilots of industrial AI.

Source: Expansión, Cinco Días

China

Leadership in Automation and Industrial AI

Industrial AI as a competitive advantage: The fourth quarter confirms a strong push in highly automated factories and data-driven decision systems.

Trade rebalancing: The reduction of exports to the U.S. continues, offset by growth toward Asia, Africa, and Latin America.

Internal efficiency strategy: The focus shifts from volume to productivity, quality, and operational cost reduction.

Source: Nikkei Asia, South China Morning Post

Conclusion

The October–December 2025 period consolidates key structural trends:

Nearshoring in Mexico enters a phase of maturity, where industrial efficiency is critical.

Europe and Spain strengthen their commitment to digitalization and sustainability as pillars of competitiveness.

The United States prioritizes modernization and automation over aggressive expansion.

China accelerates its leadership in automation and industrial AI applied to the shop floor.

Global manufacturing enters 2026 with a clear demand: more control, more intelligence, and greater operational resilience.

From Industry Labs, we support our clients in this transition toward Advanced Manufacturing 4.0 and 5.0, integrating MES, APS, SGA, IIoT, and Agentic AI to turn uncertainty into a competitive advantage.

Do you have relevant news about your company or sector that could be of interest to our community of more than 5,000 industrial companies?Share it Share it with us and we will be happy to spread it through our newsletter so it reaches our entire network of industrial professionals.

Industry Labs

A Prosperous 2026

In industry, a new year is measured in decisions, people, and results.

2025 has been a year of resilience, of plants that never stop and teams that keep moving forward even in uncertain environments.

At Industry Labs, we share that culture, because we are industrial, just like you. For decades we have worked from the reality of the shop floor, creating solutions that help bring order, optimize, and make better decisions.

Looking toward 2026, our wish is both simple and profound:

more robust processes, better-informed decisions, smarter plants, and more empowered teams. May technologybe a silent ally that frees up time and talent without losing humanity.

We will continue by your side, 360 degrees, from operations and planning to plant intelligence and cognitive digitalization, with industrial rigor and a future-focused vision.

Thank you for trusting Industry Labs.

A Prosperous and Successful 2026!

Thank you for continuing to trust us!

Warm regards and until the next newsletter.

The Industry Labs teamLabs for Smart Manufacturing

| Five well-spent minutes

What´s new on December 2025?

Highlights, insights, and interesting opportunities — let’s dive in!

Agentic AI Orchestration and Governance by Industry Labs

Agentic AI only creates value in industry when it is built on a solid foundation of digitized core processes. The first step is to digitalize transactional processes with Industry MES, Industry APS, Industry SGA, which digitize and optimize operations and generate reliable data. Without this foundation, any attempt at AI becomes fragile and difficult to govern.

Once operational processes are digitized, the next level is to incorporate plant digitalization, in order to analyze OEE, explain downtime, and truly understand what is happening in the operation.

Only then does it make sense to advance toward the cognitive digitalization of critical business processes through Agentic AI Orchestration & Governance by Industry Labs, ensuring security, determinism, and a clear human-in-the-loop strategy, where AI assists and proposes, but human control remains.

The message is clear: the cognitive industry does not start with Agentic AI, it starts with well-digitized transactional processes. Those who follow this path will be able to scale intelligence in a safe and controlled way, with real impact on decision-making and a clear ROI.

Discover more at www.industrylabs.biz

Ready to get started? Write to us and let’s build together the next generation of intelligent industry.

Glossary (summary):

Agentic AI: AI based on specialized agents that reason and act under control rules.

MES: Manufacturing Execution System for real-time production execution.

APS: Advanced Planning and Scheduling of production.

SGA: Warehouse Management System for internal logistics and optimization.

OEE: Overall Equipment Effectiveness, a metric for the overall efficiency of production equipment.

Orchestration & Governance: the layer that governs and controls how AI agents act.

Human-in-the-loop: human supervision and decision-making over AI.

ROI: return on investment.

Industry Labs

Industry Labs Accelerates Its Growth in 2025 Through Alliances with SAP Gold Partners

In 2025, Industry Labs is accelerating its growth thanks to a clear and effective strategy based on alliances with SAP Gold Partners. Through these collaborations, Industry MES and Industry APS are natively integrated with SAP Business One and SAP ByDesign, transforming them into true industrial ERPs, capable of governing not only administrative management, but also production planning and execution.

This combination allows companies to keep SAP ERP as their corporate core while incorporating shop floor control, traceability, advanced planning, and operational optimization. The model is generating real and sustained business for Industry Labs , especially among industrial companies seeking efficiency and control without replacing their ERP. The outlook for these alliances is particularly strong in Central America, Mexico, South America, and Spain, where Industry Labs , together with SAP Gold Partners, is consolidating itself as a key player in industrial modernization and as the foundation for future cognitive digitalization.

Industry Labs

Industry Labs 2026: 360° Industrial Enablement, from Transactional Digitalization to Cognitive Intelligence

Looking ahead to 2026, Industry Labs is strengthening a very clear market positioning: we support our clients in a 360-degree journey, from the operational foundation to the cognitive layer of the business. Our culture is industrial—just like our clients’—and we have spent more than two decades building Advanced Manufacturing 4.0 solutions and platforms grounded in the reality of the shop floor.

That journey begins with the digitization and optimization of critical transactional operational processes, through the implementation of Industry MES, Industry APS, and Industry SGA, which structure and optimize execution, planning, and logistics, generating reliable data. On top of that foundation, we integrate plant intelligence through IIoT, to understand OEE, explain downtime, correlate performance, and anticipate deviations.

And only when processes and data are mature, we complete the journey with the cognitive digitalization of critical business processes through Industry Agentic AI Orchestration & Governance, always ensuring security, determinism, and a clear human-in-the-loop strategy.

The result is a more efficient, resilient, and aware industry, where technology does not just automate, but truly helps companies operate and decide better.

News of Interest for Our Clients

News of Interest for Industry Labs Clients in Spain

Spain postpones the entry into force of Verifactu, the electronic invoicing system promoted by the Tax Authority, until 2027

Spain has postponed the mandatory adoption of Verifactu until 2027 to facilitate the adaptation of companies and self-employed professionals, but the change is already underway. Verifactu introduces verifiable invoicing through certified software, with complete, traceable, and unalterable invoices, QR codes, and the possibility of automatic submission to the Tax Authority.

The new dates are: January 1, 2027 for Corporate Income Tax companies and July 1, 2027 for self-employed professionals. Even so, starting in 2025, invoicing software must comply with the technical requirements, so adaptation must begin in advance.

In this context, as of October 2025, the Industry ERP is already prepared to comply with Verifactu, allowing companies to get ahead, ensure traceability, and avoid last-minute rushes. Verifactu is not just about tax compliance: it requires reviewing ERPs, accounting processes, and compliance models. Those who prepare now will reduce risks and costs and will reach 2027 with a competitive advantage.

Do you have questions or need assistance? Write to us and we will be happy to help.

Manufacturing News Octubre - Diciembre 2025 by Industry Labs

During the last quarter of 2025, the global manufacturing industry has entered a phase of strategic adjustment and positioning for 2026. In addition to geopolitical volatility, there are clear signs of selective slowdown, more targeted investments, and a tangible acceleration in advanced digitalization, automation, and industrial intelligence.

Below is the country-by-country summary:

United States

Focus on Selective Reindustrialization and Operational Efficiency

PMI stabilized, without strong growth: The manufacturing index remained around 49–50during the quarter, reflecting stability without a clear recovery.

More pragmatic reindustrialization: Federal incentives continue, but with greater demands for returns and productivity. Modernization projects of existing plants are growing compared to new construction.

Automation as a priority: Increased investment in MES software, advanced planning, and industrial analytics to offset labor costs and inflationary pressure.

Source: Bloomberg, Wall Street Journal

México

More mature and demanding nearshoring

Nearshoring is consolidating: The pace of new investments remains steady, especially in automotive, food, and consumer goods, with strong demand for industrial digitalization.

Structural bottlenecks: Energy, water, and logistics remain critical factors that constrain the pace of expansion.

Shift in focus: Established companies are prioritizing operational efficiency, traceability, and shop floor control over purely volumetric growth.

Source: El Financiero, El Economista

Spain

Year-end marked by industrial digitalization

Industry and European funds: In the last quarter, projects financed by PERTEs and Next Generation fundsaccelerated, with a focus on digitalization and sustainability.

Strong interest in MES, APS, and IIoT: industrial SMEs are intensifying investments in Advanced Manufacturing platforms to improve productivity and resilience.

Preparing for 2026: the industrial agendaincreasingly incorporates operational intelligence concepts and early pilots of industrial AI.

Source: Expansión, Cinco Días

China

Leadership in Automation and Industrial AI

Industrial AI as a competitive advantage: The fourth quarter confirms a strong push in highly automated factories and data-driven decision systems.

Trade rebalancing: The reduction of exports to the U.S. continues, offset by growth toward Asia, Africa, and Latin America.

Internal efficiency strategy: The focus shifts from volume to productivity, quality, and operational cost reduction.

Source: Nikkei Asia, South China Morning Post

Conclusion

The October–December 2025 period consolidates key structural trends:

Nearshoring in Mexico enters a phase of maturity, where industrial efficiency is critical.

Europe and Spain strengthen their commitment to digitalization and sustainability as pillars of competitiveness.

The United States prioritizes modernization and automation over aggressive expansion.

China accelerates its leadership in automation and industrial AI applied to the shop floor.

Global manufacturing enters 2026 with a clear demand: more control, more intelligence, and greater operational resilience.

From Industry Labs, we support our clients in this transition toward Advanced Manufacturing 4.0 and 5.0, integrating MES, APS, SGA, IIoT, and Agentic AI to turn uncertainty into a competitive advantage.

Do you have relevant news about your company or sector that could be of interest to our community of more than 5,000 industrial companies?Share it Share it with us and we will be happy to spread it through our newsletter so it reaches our entire network of industrial professionals.

Industry Labs

A Prosperous 2026

In industry, a new year is measured in decisions, people, and results.

2025 has been a year of resilience, of plants that never stop and teams that keep moving forward even in uncertain environments.

At Industry Labs, we share that culture, because we are industrial, just like you. For decades we have worked from the reality of the shop floor, creating solutions that help bring order, optimize, and make better decisions.

Looking toward 2026, our wish is both simple and profound:

more robust processes, better-informed decisions, smarter plants, and more empowered teams. May technologybe a silent ally that frees up time and talent without losing humanity.

We will continue by your side, 360 degrees, from operations and planning to plant intelligence and cognitive digitalization, with industrial rigor and a future-focused vision.

Thank you for trusting Industry Labs.

A Prosperous and Successful 2026!

Thank you for continuing to trust us!

Warm regards and until the next newsletter.

The Industry Labs teamLabs for Smart Manufacturing

You're one step away from leading the new industry

Schedule a personalized demo.

Discover how our AI Companion platforms can transform your operation in just a few weeks.

You are one step away from

leading the new industry

Request a personalized demo.

Discover how our AI Companion platforms can transform your operations in just a few weeks.

You are one step away from

leading the new industry

Request a personalized demo.

Discover how our AI Companion platforms can transform your operations in just a few weeks.

You are one step away from

leading the new industry

Request a personalized demo.

Discover how our AI Companion platforms can transform your operations in just a few weeks.